Casting is a process which has been used in various forms over the last 5,000 years. It is argued that the first true metalworking skill was that of casting (investment or lost-wax casting). Cast silver holds a great appeal due to its fine quality and superior gauge of silver. Cast items are handmade, often in two halves, resulting in fine and delicate detail. Casting was the method of choice for many renowned silversmiths such as Paul Storr and Paul de Lamerie.

There are different types of casting used for different types of materials and metal; we are interested in those used with silver. Silver has considerable strength and a low melting point which makes it an ideal metal to be cast without difficulty. Here we will be looking into the technical background of the process that is casting.

Casting Silver

In its simplest form, casting silver is when liquid metal is poured into a mould and is left to set; once hardened the piece will take on the form of the shaped die… The disadvantage of this is that objects will be flat on one side however, to get a full 3D object two halves of a mould are made symmetrically and then sealed together. Interestingly, due to the mould being closed, ventilation holes are placed to allow the metal to set and gases to escape and due to this sprues are left behind, which have to be cleaned off the finished product.

Early Types of Mouldings

In the very early days stone was used as a mould, with the sixteenth century seeing the utilisation of sand moulds . In this style of die the object which was to be cast was compacted into the sand to make an impression or indentation.

Another type of casting is slush-casting. Slush casting was created to make hollow objects which saved on metal and produced lighter objects; this process is only suitable for certain types of metals. When the molten metal hits the cold walls of the mould it hardens quickly, allowing further still molten metal to be poured out.

Investment or Lost-Wax Casting

Since the fourth millennium BC this type of casting has been the most used casting process. With this method…

- A wax model is crafted of the object to be cast, the core of which is changed depending on if the finished piece is to be hollow or solid.

- The model is then fitted with the all-important ventilation vents using wax sprues.

- The model is invested (covered with plaster or clay) and left to harden.

- Once set the clay/plaster is heated gently or baked. The heat causes the wax to melt which drains from the mould and is replaced by the molten metal.

- Once cooled the mould is then removed to reveal the cast piece. If a piece is to be mass produced a master mould is kept to make future moulds; which in today’s modern age is usually made from silicone-rubber, however, in the past it would have been lead or plaster.

- Once removed from the mould the cast piece could go through the cleaning up process, where all dirt, scales and sprues caused from ventilation holes and core supports are removed.

- Any sharpening of the piece is done along with polishing.

Although the modern age has introduced heavy machinery to help with mass production of cast silver, the basic forming techniques of casting are still to this day done by hand. I’m sure you can agree after reading this that casting is certainly a craft and can produce such beautiful pieces.

Take these magnificent, fine impressive pair of antique George IV English cast sterling silver candlesticks for example. These cast sterling silver candlesticks are the finest gauge and examples of their type you could hope to acquire; the most magnificent pair of this type Andrew Campbell has had the pleasure to include within his inventory.

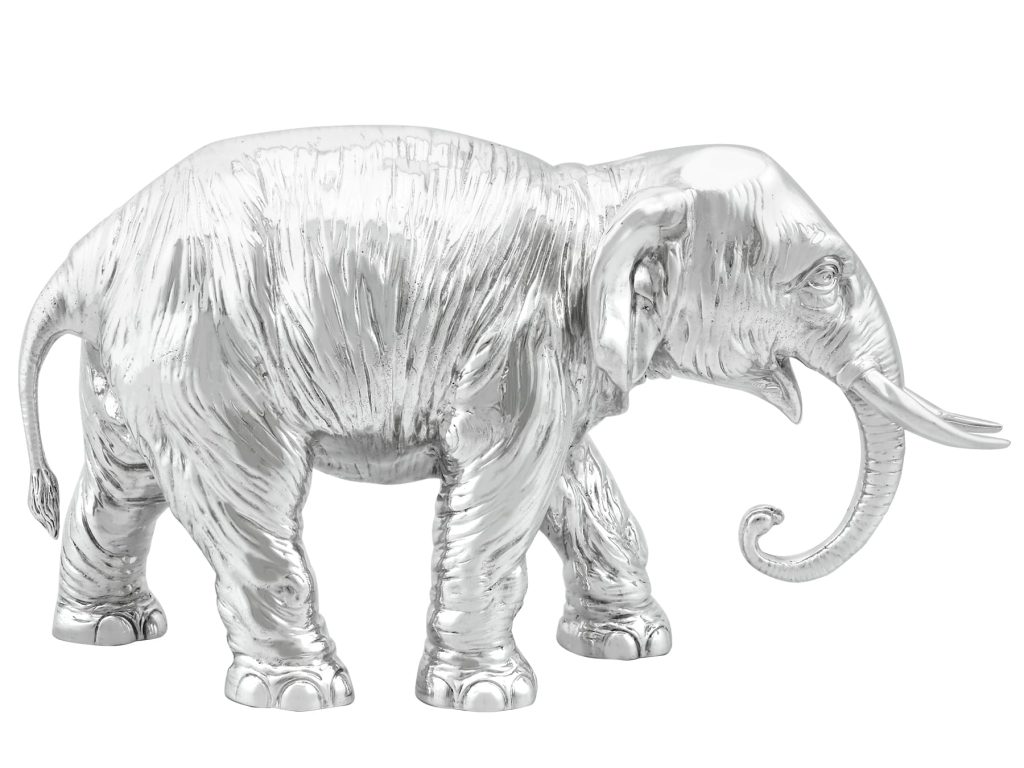

The use of casting has allowed this hollowed box to have fine details replicating not only the undulating anatomy of the elephant but the textured details of the skin and eye socket.

Casting this magnificent silver jug has allowed the silversmith to provide almost a work of art of classic depictions in the form of a ewer.

Any plain item can be enhanced with cast designs, which are then applied, as seen in this silver bowl. The figural masks and medallions, in addition to the classic rams head motifs – these enhance such a plain bowl to create something of greater detail.

2 Responses

i have a silver cast ice bucket from 1909. it is signed and stamped and most likely of the first pilgrim wedding. do you know who would be best at reading the four stamps?

thank you.

jackie turner

Hey,

Thanks for your comment, if you are referring to the hallmarks, you may find the links below helpful:

http://www.silvermakersmarks.co.uk

http://www.925-1000.com

http://www.silvercollection.it